Better Temperature Control in Reefer Trailers with Passive Cooling

The Challenge

How can fleets reduce thermal load and fuel consumption while improving temperature stability for temperature sensitive cargo?

Refrigerated trailers must keep their contents cool, while operating under constant exposure to intense solar radiation, particularly in regions with year-round sun. Traditional aluminum trailer roofs can reach surface temperatures up to 70°C. This intense heating radiates into the trailer interior through the insulation and steel roof supports, raising interior wall temperatures and forcing refrigeration units to work harder to maintain setpoints. The result is higher diesel fuel consumption and increased wear on refrigeration components.

The Solution - PolyFrost

PolyFrost, ChillSkyn’s passive cooling coating, was spray-applied over a new 53′ refrigerated trailer to compare the thermal performance of its coated roof against an identical trailer with a bare aluminum roof.

PolyFrost is engineered to reflect solar heat, maintain cooler roof surfaces, and reduce thermal transfer into vehicle interiors.

PolyFrost

PolyFrost is a spray-applied, passive radiative cooling (PDRC) coating designed for sun-exposed surfaces in transport and industrial applications.

Reflects Solar Radiation

Reduces surface heating.

Maintains Cooler Interiors

Without adding additional energy demand.

Scalable and Easy to Apply

Using standard spray equipment, just like paint, in under 12 hours.

Effortless Maintenance

Regular cleaning with soapy water ensures long lasting peak performance.

Results

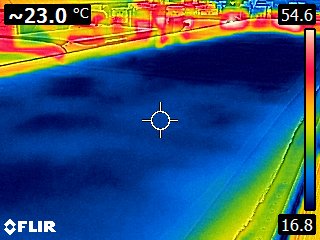

Field Trial

- Celaya, Mexico - February 27, 2025

- Solar radiation: 2:00 pm - 900 W/m2

- Outdoor temperature 28°C (82°F)

PolyFrost coated roof – 6°C (10°F) temperature reduction

No active cooling used

Performance Comparison | |

|---|---|

Internal temperature of Bare aluminum trailer | 34°C (93°F) |

Internal temperature of POLYFROST coated trailer | 28°C (82°F) |

Internal temperature drop with POLYFROST | 6°C (10.8°F) |

Key Impacts

Reduced refrigeration workload

Cooler roof and wall temperatures mean the reefer unit cycles on less often in start-stop mode, lowering total runtime.

Lower fuel consumption

Shorter pull-down times and fewer compressor cycles translate into reduced diesel use and operating costs.

Extended equipment life

Reducing the workload on the refrigeration system helps limit wear on compressors and related components.