Passive Cooling for Aluminum-Body Dry Boxes

The Challenge

How can dry van fleets reduce thermal load while improving temperature stability for sensitive cargo?

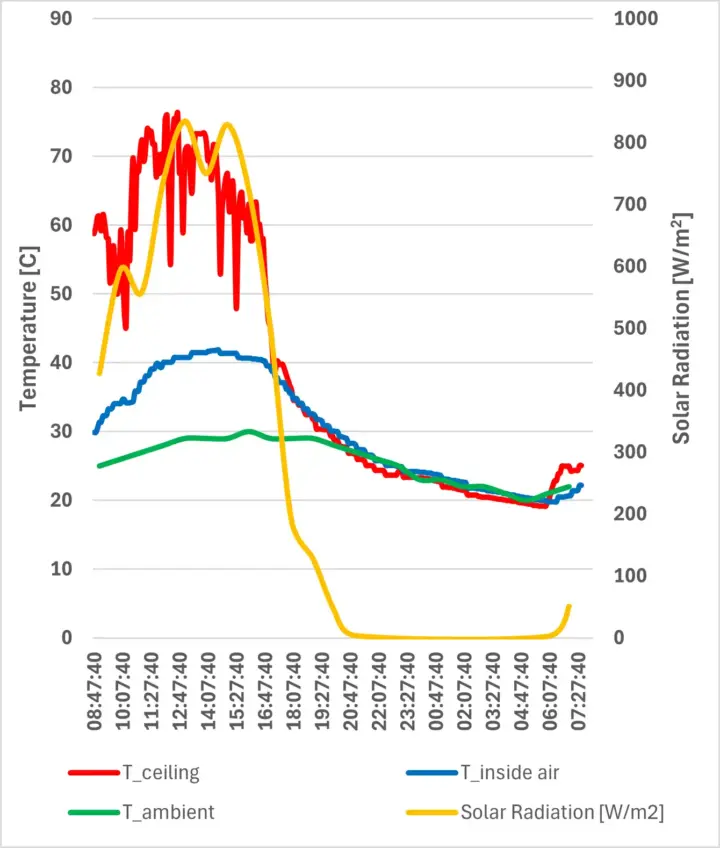

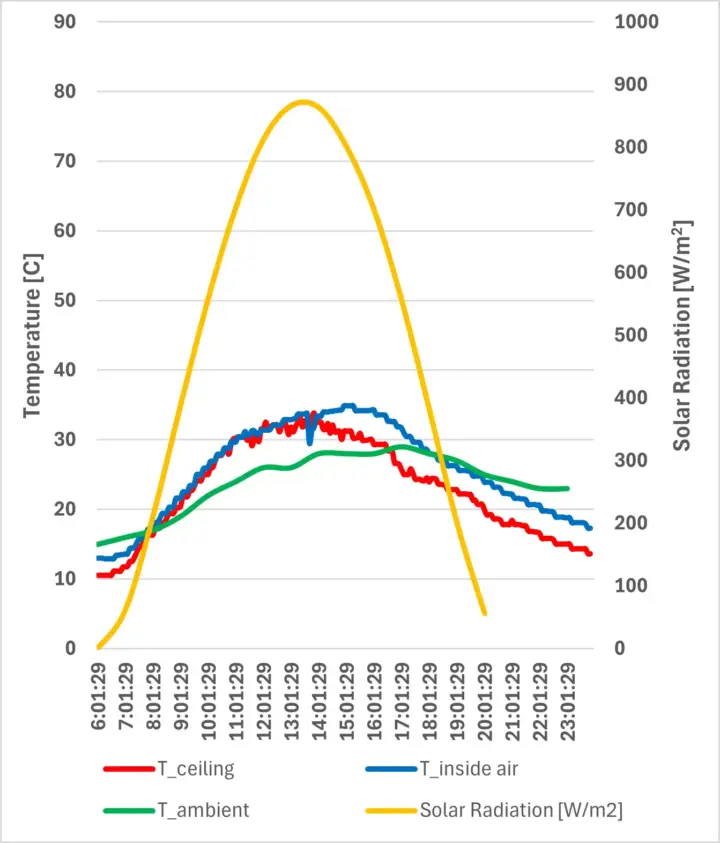

Aluminum-body dry boxes, commonly used to transport sensitive goods, face extreme heat loads while operating, particularly in regions with year round sun. Traditional aluminum trailer roofs can reach surface temperatures up to 70 °C. With little to no insulation and no active cooling system, interior air temperatures can climb rapidly, often exceeding safe limits for both cargo and crews during loading or unloading.

The Solution - PolyFrost

PolyFrost, ChillSkyn’s passive cooling coating, was spray-applied over a 20′ aluminum dry box to compare the thermal performance of its coated roof against an identical trailer with a bare aluminum roof.

PolyFrost is engineered to reflect solar heat, maintain cooler roof surfaces, and reduce thermal transfer into vehicle interiors.

PolyFrost

PolyFrost is a spray-applied, passive radiative cooling (PDRC) coating designed for sun-exposed surfaces in transport and industrial applications.

Reflects Solar Radiation

Reduces surface heating.

Maintains Cooler Interiors

Without adding additional energy demand.

Scalable and Easy to Apply

Using standard spray equipment, just like paint, in under 12 hours.

Effortless Maintenance

Regular cleaning with soapy water ensures long lasting peak performance.

Results

Field Trial

- Terrebonne, QC, Canada - August 2025

- Peak Solar Radiation: 920 W/m2

- Peak outdoor temperature 35°C (95°F)

Performance Comparison | |

|---|---|

Internal temperature of Bare aluminum trailer | 41 – 45°C (93°F) |

Internal temperature of POLYFROST coated trailer | 31 – 35°C (82°F) |

Internal temperature drop with POLYFROST | up to 10 °C (18°F) |

Key Impacts

Cooler Interior

With no active cooling, aluminum dry boxes absorb heat fast. Applying ~100 um PolyFrost (≈90% solar reflectance) to the roof only delivered a significant drop in internal air temperature under direct sun.

Cooler internal temperatures protect sensitive goods, reduce the potential for product loss, and create safer, more comfortable conditions for crews during loading and unloading.